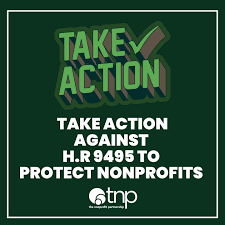

What is H.R. 9495?

If passed, this bill would give the Treasury Department the power to revoke a non-profits’ tax-exempt status simply by labeling theme a “terrorist supporting” organization. There would be no due process, no evidence, and no accountability required . . . leaving nonprofits defenseless against vague and potentially politically motivated accusations.

A vote will happen as early as tomorrow and your action is needed today to stop this dangerous bill. Call the Capitol Switchboard (202) 224-3121 and ask to be connected to your Representative’s office.

Only a simple majority is needed to pass . . . so every member of Congress is critically important. Let’s flood their offices with calls. The nonprofit organizations that sustain our communities re at risk. Please take immediate action and tell your member of Congress to oppose H.R. 9495!

For more information and a sample script for your call, please visit this blog from our friend Vu Le at Nonprofit AF.

0 Comments